Guest Page No. 4

More From Close To Home

Heage Windmill

|

November

2004 - Earlier this year I visited the windmill at Heage

and showed several photos from there elsewhere on this site -

click here

to view. Since then, one of the volunteer guides who works

at the mill has contacted me sending a number of images that

have been taken on the dust floor of the mill where visitors

are not normally allowed for safety reasons. A Fuji 4900 x 6

zoom camera was used to capture the images and all the information

that accompanies them has also been provided by the photographer. November

2004 - Earlier this year I visited the windmill at Heage

and showed several photos from there elsewhere on this site -

click here

to view. Since then, one of the volunteer guides who works

at the mill has contacted me sending a number of images that

have been taken on the dust floor of the mill where visitors

are not normally allowed for safety reasons. A Fuji 4900 x 6

zoom camera was used to capture the images and all the information

that accompanies them has also been provided by the photographer.

All images are copyright protected and used with permission.

|

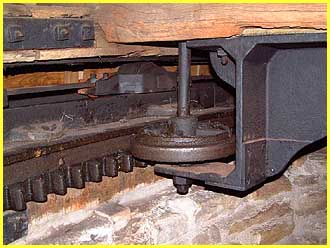

This image shows one of the six truck wheels that run

on the inside of the curb and help keep the mill cap centralised.

|

This view is looking up beyond the gear on the dust floor to

the apex of the wooden O'gee cap.

|

This is the hoist that raises the sacks of corn to the

Bin Floor. It is friction driven from a wheel rubbing on the

underside of the wallower gear, the wallower being the gear that

changes the rotation of the wind shaft from horizontal to vertical.

|

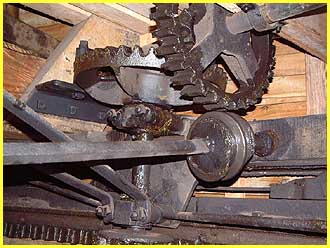

Disaster would strike if the sails were not kept in the correct

position and this shows a few of the gears involved in the drive

train from the fantail. This drive rotates the cap and keeps

the sails facing into the wind.

|

The sails of the mill, despite appearances from a distance, are

not solid but are made up of a number of shutters. This close

up shows the rotating end of the striking gear. This rod passes

through the centre of the hollow windshaft and it is this mechanism

which allows the miller to control the angle of the sail shutters.

|

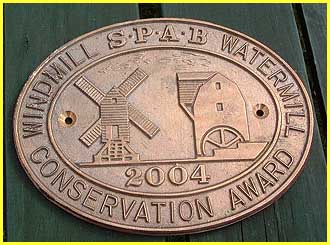

The Society for the Protection of Ancient Buildings (SPAB) is

a national body that has been giving awards since 1991 for outstanding

restoration, involvement of the local people and the ability

to carry out maintenance in the future to the present standard.

To date very few have been awarded but Heage Mill has been the

proud recipient of No. 12.

|

The mill is closed for winter maintenance/improvements

and at the time of writing a new spring loaded leather wiper

is being made to ensure that the flour which spills out of the

millstones circumference is taken around the receiving track

and into the floor exit hole. When the mill is working it is

not possible to see the wiper as it is covered by the wooden

tun but when the mill re-opens next year I'm sure it will be

in tip top condition. You can find out more about the mill here.

|